TWE Nonwovens US specializes in engineered applications utilizing nonwoven thermal bonded and needlepunched technologies. Each facility provides advanced measurement and accuracy through detailed controls and expert personnel, placing TWE Nonwovens US at the forefront of quality aspects like: web density, thickness control, blending and polymer science, permeability, absorption, and insulation.

TWE Nonwovens US specializes in engineered applications utilizing nonwoven thermal bonded and needlepunched technologies. Each facility provides advanced measurement and accuracy through detailed controls and expert personnel, placing TWE Nonwovens US at the forefront of quality aspects like: web density, thickness control, blending and polymer science, permeability, absorption, and insulation.

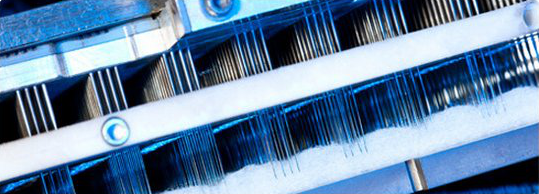

Each TWE Nonwovens US facility encompasses innovation through engineering and implementation of some of the most technical and state-of-the-art production processes in the industry.

Our Processes

TWE Nonwovens US’s processes are advanced in the following areas:

- Blending techniques + consistency

- Web control

- Integrated computer controls

- State-of-the-art temperature regulation and through air bonding

- Consistent winding and slitting controls

- Progressive nonwoven and fiber science laboratory

Fiber Technology and Dimensional Ranges

- All types of natural, synthetic, and recycled fibers in range of 1-40 denier can be utilized

- Weight: 70 gsm – 1450 gsm

- Width: 300mm – 4.5m

- Thickness: 3mm – 200mm

Blending

- Accurate, consistent, and highly intimate blends through continuous blending + weighing technologies

- Better homogeneity and more consistent uniform fiber distribution equates to more reliable and repeatable nonwoven product performance

Web Forming

- Incomparable web quality and consistency

- Continuous and automatic optimization of MD and CD evenness

- Web density control through continuous monitoring yields accuracy of weight distribution in both directions in the final product

- State-of-the-art web formation yields optimum fiber distribution and orientation for enhanced product performance + production

Thermal Bonding

- Continuous monitoring and control of air flow and temperature for uniform and consistent web bonding

- Maximizes product consistency and internal bond strength through the cross section of the batt

- Proprietary cooling and quenching process accurately calibrates product thinkness

- Yields repeatable thickness product to product, lot to lot for consistent product quality

Winding/Slitting

- Perforating, slitting, and winding components in combination with control of tension, nip, and torque preserves the characteristics and quality of the web in the finished product